OUR PROJECTS AND SERVICES

D K Robotics Automation provides Turnkey Robotics Automation Solutions and industrial Robotic Programming Services to industries. We work with some of the largest industrial companies across many fields, including automotive, Forging, Foundries, Domestic Appliances, Engineering, Fabrication industries and many more.

At D K Robotics We offer following

- Robotics Turnkey Automation Solutions / SPM

- Robotics Programming Services

- Robot Maintenance Services

- Installation and commissioning of automation cells.

- Robot Spare Parts (Used / New)

- Fabrication and machining of automation cell equipment’s.

1) Robotics Turnkey Automation Solutions / SPM

- Robotic Pick and Place cell

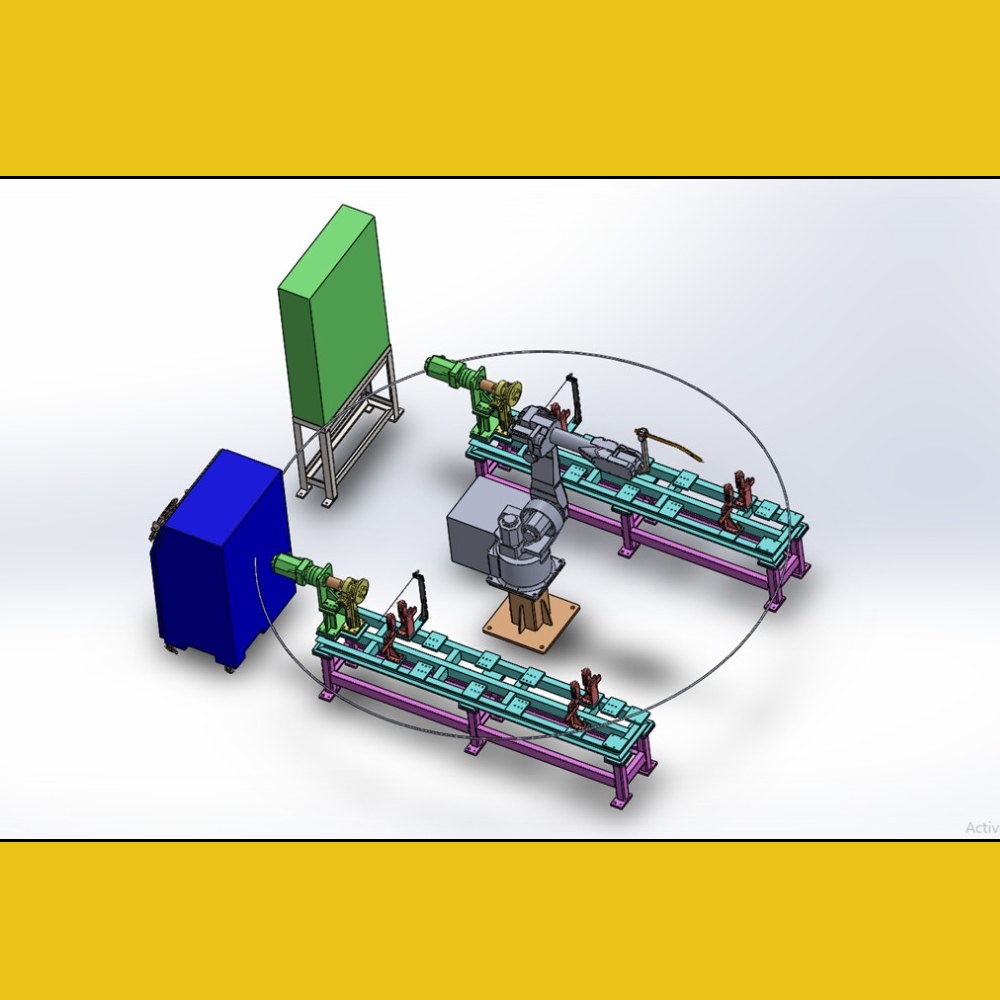

- Welding Automation – MiG, TiG, Arc, Laser, Spot etc.

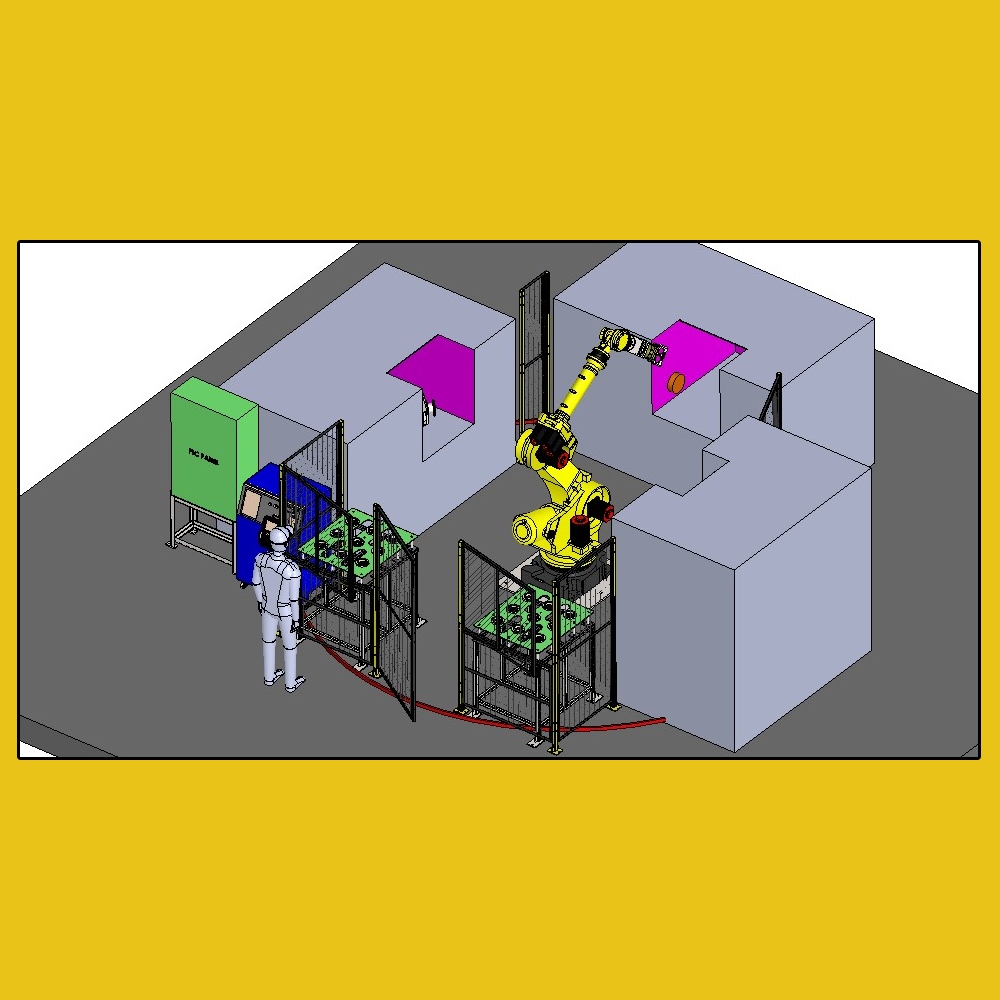

- Machine Tending (CNC, Press machine etc.)

- Material Handling

- Deburring / Grinding

3) Robot Maintenance

- Robot Breakdown Maintenance support

- Robotic System Annual Maintenance Contract (AMC)

- Preventive Maintenance

- Robot overhauling / reconditioning

- Onsite robot Maintenance

- Robot Health checkup

- Repairing of Robot Servo motors, encoder and power cables, power supply and control modules, teach pendant etc

- Robot software loading, configuration, taking & loading backup, Robot calibration, Mastering etc

5) Robot Spare Parts

- Robot servo motors, power and encoder cables, connectors

- Teach pendant cables, connectors

- Power supply, Amplifier boards and other modules

- CPU and Manipulator batteries

- Memory cards and adaptors, compact flash cards

- Robotic Cell spares like Variable Frequency Drives (VFD), Proximity Sensors, Optical sensors, light curtains, PLC modules etc

- Welding spares – Torch cables, Feed rollers etc

2) Programming Services

- Robot Programming Service for Fanuc, ABB, Kuka, Kawasaki, Yaskawa etc

- Onsite programming Service

- Production support

- Support for Program Logic Development

- Programming services for applications like Pick and place, welding, Machine tending, Palletizing, material handling, Deburring and grinding, BIW etc

- Establish various communications in robot like Device Net, Ethernet, Profinet, Profibus with PLCs and other equipments.

- PLC programming support in Delta, Mitsubishi, Siemens.

- Offline programming Applications (OLP)

- Simulation Service.

- Onsite robot training

4)Installation and Commissioning of Robotics cell

- Complete Cell layout preparation and marking as per drawing

- Robot & cell equipment installation and commissioning.

- Cable trays and cable laying, terminations, grouting etc

- Gripper assembly and trials

- Pneumatics preparation, laying /routing etc

- Robot dress pack preparation and routing.

- PLC panel

6) Mechanical fabrication and machining

- Design and manufacturing of welding fixtures and positioners.

- Fabrication of robot mounting pedestal / plates.

- Fabrication of safety fence as per requirement.

- Material handling trolleys

OUR SERVICES

Refurbished Fanuc Robot R2000iA

Delta PLC

Kuka Robot

Fanuc Robot

Refurbished Fanuc Robot M120iB

Robotic Machine Tending Cell

Robotic Machine Tending Cell

ABB Robot Battery

Robot Maintenance

Robotic Welding

ABB Robot Battery

Robotic Machine Tending Cell

Kawasaki Robot Battery